A success story, since 1985

24.08.2022

With high tech, high speed and high quality, Pankl Racing Systems has been one of the world‘s leading developers and producers of engine, chassis and drivetrain components since 1985. Pankl not only supplies the racing industry, but also the sports car and aviation industries with innovative products.

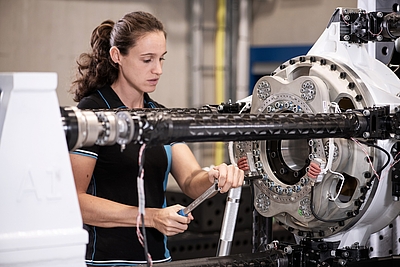

Pankl Racing Systems AG specialises in the development and production of engine, chassis and drivetrain systems for racing, high-performance vehicles and the aviation industry. The company impresses with lightweight components made of high-quality materials and designed for extreme mechanical loads. The parts are manufactured completely in-house – from the initial design, through finite element analysis, to production and test beds, Pankl covers the entire product development process. Thanks to its years of experience and the expertise of the entire team, Pankl is regarded as a technology leader, and supports its customers with innovative solutions to become even better.

One-stop-shop for racing, high performance and aerospace

Quickly adapting new technologies, production methods or materials and incorporating them into existing processes is probably one of Pankl‘s greatest strengths. With this competitive advantage, the company regularly establishes new benchmarks in the field of lightweight construction. High-precision measuring and production facilities, as well as the various engine and drivetrain test beds, ensure that lightweight components can be manufactured and validated to meet the customer‘s toughest performance requirements.

Additive manufacturing: Future technology in series production

Pankl Racing Systems uses state-of-theart production technologies in many areas. When it comes to innovative lightweight solutions, 3D metal printing in particular offers a huge amount of potential. Pankl has succeeded in bringing together what is to date the largest cooperation between leading technology enterprises under a single roof in the form of the Pankl Additive manufacturing competence center in Kapfenberg, with a view to establishing additive manufacturing technologies in new applications.

From track to road

In cooperation with voestalpine Böhler Edelstahl, EOS and Quintus Technologies, Pankl Racing Systems is pursuing the goal of expanding the boundaries of lightweight construction and specifically deploying this technology in the high-performance automotive and aerospace sectors. For years, Pankl has used motorsport as its playground for developing and testing new ideas. Combined with expertise from the field of industrialisation, lightweight construction innovations in motorsport can be quickly adapted for the sports car sector. This means that Pankl can serve a wide range of industries with its entire product range – from prototype building to series production.

Targeting the nextsustainability goals with lightweight

All state-of-the-art mobility strategies now require a high lightweight component content in order to meet sustainability goals. With its development know-how and modern manufacturing technologies, Pankl helps its customers to achieve these targets and has therefore become the leading technology partner for engine, chassis and drivetrain components in the racing and automotive sectors. Pankl Racing Systems is headquartered in Kapfenberg in Styria, Austria. The company‘s ten facilities worldwide are managed from there. Pankl‘s technological expertise encompasses machining technology, heat treatment, forming technology and additive manufacturing.

Pankl Racing Systems AG

Industriestraße West 4, A-8605

Kapfenberg

+43 3862 33 999-0

office@pankl.com

www.pankl.com/racing